Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

Hydroxypropyl Methyl Cellulose (HPMC) is one of the most widely used cellulose ethers in modern construction chemistry. From tile adhesive and wall putty to gypsum-based materials and detergent formulations, HPMC provides essential rheology, water retention, thickening, and workability.

This article explains what HPMC is, how it is produced, and how it enhances performance across different applications. It also discusses how manufacturers like Celix optimise HPMC grades for professional users.

HPMC is a non-ionic cellulose ether derived from natural purified cotton or wood pulp. Through etherification with methyl chloride and propylene oxide, the cellulose backbone is chemically modified to deliver excellent performance in water-based systems.

The Key properties of HPMC include water retention, thickening, binding, film formation, and dispersion stability. These properties make it a versatile additive applicable in various fields such as construction and coatings, where it improves material properties, enhances application efficiency, and increases product durability.

Water solubility

High water retention

Thermal gelation

Thickening and rheology modification

Because HPMC is non-ionic, it remains stable in cementitious, gypsum, and polymer systems.

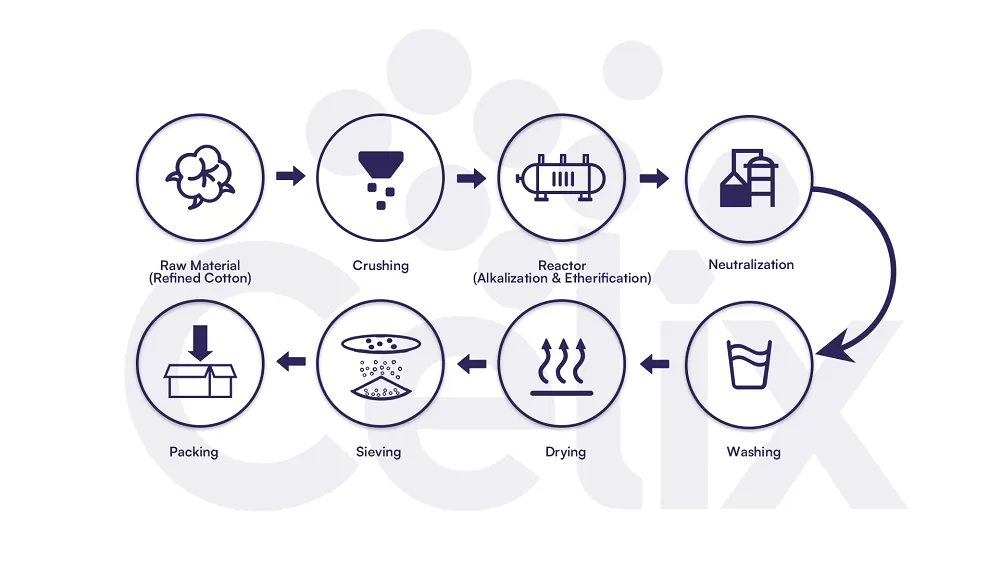

As a premium cellulose manufacturer, the production of HPMC in CELIX involves several stages. Celix HPMC Manufacture Process

1. Raw Material Cotton Crushing

The Fine cotton (made from cotton linters) is ground into powder of the required size at this step.

2. Alkalization & Etherification of Cellulose

The HPMC cellulose reacts with sodium hydroxide to activate hydroxyl groups in the reactor kettle. In Celix, we have four production lines to complete the alkalization process in full digitalisation. Methyl chloride and propylene oxide react with the activated cellulose, introducing methoxy (–OCH₃) and hydroxypropyl (–CH₂CHOHCH₃) groups.

Celix Liquid alkali storage tank Celix Reaction Kettle

3. Neutralisation and Washing

Residual salts and by-products are removed to keep the purity of the HPMC.

4 .Drying and Milling

The HPMC powder is dried, milled, and sieved to specific particle sizes. Celix PM-75U granularity can reach 98% passing the 80 mesh.

Celix Powder Sieving Mills

Celix Cellulose Company use precise control of substitution ratios to achieve predictable viscosity, gel temperature, and water retention performance.

Celix Centrol Control Room

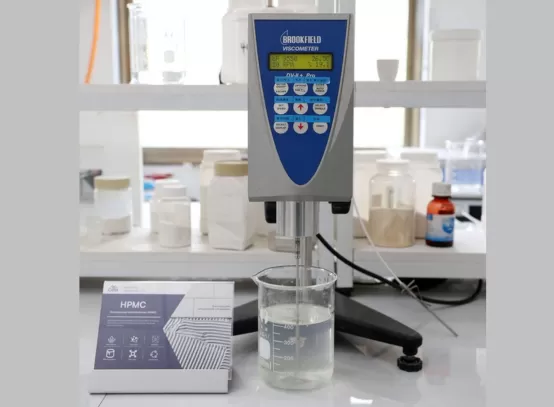

1. Viscosity

If we count in the NDJ viscosity standard, the available range is 400–200,000 mPa·s. Celix will offer you the brookfield viscosity standard so that our customers can easily match the international standard.

NDJ Viscosity (mPa·s.) | Brookfield Viscosity(mPa·s.) |

400 | 400 |

5000-10000 | 5000 |

15000-20000 | 10000 |

20000-30000 | 15000 |

35000-45000 | 20000 |

45000-55000 | 25000 |

55000-65000 | 30000 |

70000-80000 | 35000 |

85000-95000 | 40000 |

100000-110000 | 45000 |

100000-120000 | 50000 |

140000-160000 | 60000 |

180000-200000 | 70000 |

* Higher viscosity = stronger water retention and better sag resistance.

2. Particle Size

Improves dissolution rate and dispersibility. The choice of HPMC particle size primarily depends on the requirements of the end application regarding dissolution rate, powder flowability, and anti-caking properties. For example, in some applications requiring rapid dispersion and dissolution, a fine powder might be chosen, while in applications with higher requirements for powder stability, a slightly larger powder might be selected.

Prevents premature water loss

Improves open time

Enhances anti-sag performance

Recommend Celix's Model: PM-Pro-AS, PM-Pro-AST, PM-Pro-AS2T, PM-Pro-AS2T+

Increased smoothness

Better workability

Recommend Celix's Model: PM-Pro-SWP

Controls setting

Improves pumpability

Recommend Celix's Model: PM-30U

4. Detergents

Acts as a thickener and stabiliser

Recommend Celix's Model: PM-Pro-75US

Enhances viscosity and levelling

Recommend Celix's Model: PM-75U

It is the technical trend to add HPMC to the dry-mix mortar. Hydroxypropyl methylcellulose HPMC directly influences:

Bond strength

Workability

Durability

Water retention

Crack resistance

By choosing high-quality HPMC from experienced suppliers like Celix, construction manufacturers gain reliable performance for climate-specific applications.

Celix Cellulose is a trusted Chinese manufacturer of advanced cellulose ethers and green construction additives. Our products include HPMC, HEMC, HEC,RDP, Defoamer, PVA, PCE and other additives, widely applied in construction, coatings, and home care chemicals.

We're chosen by customers from Africa, Asia, Brazil, Peru, Chile, the UAE and others. We will empower global formulators with sustainable cellulose technology. If you're looking for a trusted HPMC supplier, please kindly contact Celix.

Contact Us

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.