Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

Modern construction demands materials that combine performance with sustainability. The right HPMC can make all the difference in your formulations.

Celix HPMC delivers exceptional 90%+ water retention and superior workability, optimized for construction applications through our 18 years of expertise and 30,000-ton annual production capacity.

With SGS-certified quality and global market experience across 30+ countries, our HPMC empowers formulators to achieve consistent, high-quality results.

The molecular structure of our HPMC is engineered specifically for building applications, offering five key benefits:

Celix HPMC provides balanced viscosity (from 5,000 to 200,000 mPa·s) and precise setting characteristics, giving contractors more working time while maintaining early strength development.

HPMC Water Retention Benefits

90-95% water retention (EN 13480 standard)

Prevents premature drying in thin-layer applications

Reduces shrinkage cracking in mortars

Extends open time for tile adhesives

HPMC Workability Advantages

Improves trowelability and spreadability

Enables easier finishing and compaction

Maintains consistency in varying temperatures

Reduces worker fatigue during application

These properties make Celix HPMC ideal for:

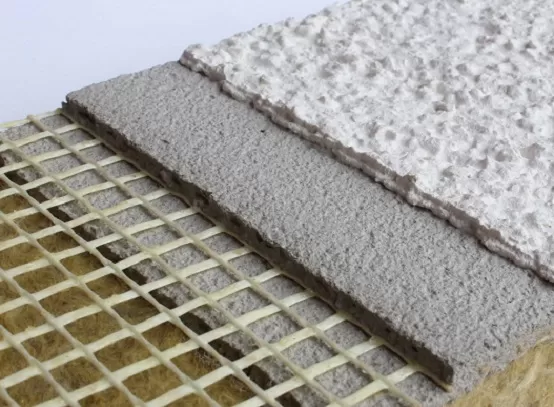

EIFS (Exterior Insulation Systems)

Tile adhesives (modified HPMC for tile adhesive, C1/C2 classifications)

Gypsum-based plaster and mortars (HPMC for gypsum mortar, HPMC for dry mix mortar)

Self-leveling underlayments

Repair mortars

Sustainability without performance compromise is at the core of our technology.

Our plant-derived HPMC is biodegradable and VOC-free, helping manufacturers meet LEED and BREEAM certification requirements while maintaining superior technical performance.

Reduced Carbon Footprint

30% lower CO2 emissions in production vs. conventional additives

Enhances durability (reducing repair frequency)

Enables lighter-weight formulations

Health & Safety Advantages

Non-toxic composition

No hazardous air pollutants

Low-dust formulations available

Compliant with EU REACH regulations

Our HPMC is particularly effective in:

Low-carbon cement formulations

Recycled material composites

Energy-efficient wall systems

Sustainable urban development projects

Local challenges require global expertise with regional adaptation.

Through our network serving 30+ countries, we provide technical support in multiple languages along with region-specific formulation advice for optimal HPMC performance.

Application-Specific Guidance

Dosage optimization charts (1.5-3.5% typical range)

Mixing procedure recommendations

Climate adaptation strategies

Technical Services

Laboratory testing support

On-site troubleshooting

Custom grade development

QC protocol implementation

Market-Specific Solutions

Latin America: High-humidity formulations

Middle East: Heat-resistant grades

Europe: Low-VOC compliant versions

Asia: Cost-performance balanced options

Celix HPMC delivers technically superior, environmentally responsible performance for modern construction needs, backed by global formulation expertise and reliable supply.

Contact Us

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.