Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

Polypropylene fiber (PP fiber) has become a cornerstone additive in modern mortar formulations, offering significant benefits in crack control, durability, and long-term performance. For companies and construction professionals looking to optimize their mixes, selecting the right PP fiber is critical. In this article, we explore how to choose the appropriate PP fiber for mortar—considering specifications, practical uses, and prevailing market trends in regions such as Europe, USA, Brazil, and Middle Asia.

When evaluating PP fiber for mortar applications, several technical specifications should guide your choice:

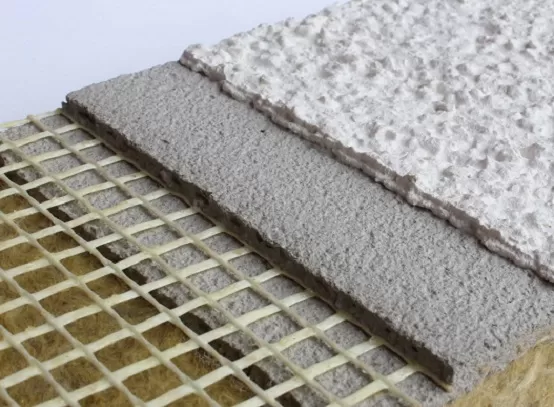

Fiber Length & Denier: Short monofilament fibers (e.g., 3 mm to 12 mm) are common for mortar. According to PP fiber manufacturers, these sizes help form a uniform micro‑network in the mortar matrix, which improves crack resistance.

Tensile Strength & Modulus: High-quality PP fiber typically has a tensile strength of ≥ 400 MPa and an initial modulus ≥ 3.5 GPa.

Melting Point / Thermal Behavior: PP fibers typically melt around 165°C, which means they can help prevent spalling under fire (by melting and creating micro-channels).

Chemical Resistance: Since mortar often has a high pH environment, PP fiber must resist alkalinity. Polypropylene is inert in high-pH cementitious matrices, making it stable over time.

Dosage: Research shows that relatively low dosages (for example, around 0.1–0.3% by volume or weight, depending on mix) can significantly improve crack control without drastically reducing workability.

Fiber Shape / Fibrillation: The shape (monofilament vs fibrillated) affects dispersion, bonding with the cement matrix, and crack-bridging behavior. Studies report that fiber geometry plays a key role in performance.

PP fiber is versatile and can be used across a range of mortar applications:

Anti-crack Mortar & Plaster: By adding PP fiber, mortar resists plastic shrinkage and drying shrinkage cracks, which enhances its durability.

Shotcrete / Sprayed Mortar: In infrastructure like tunnels or swimming pools, PP fibers boost cohesion, bonding, and impact resistance.

Industrial Flooring: For concrete mortar overlays or screeds, PP fiber helps control micro-cracks, improving toughness and reducing maintenance.

Seismic / Durable Structures: In regions with seismic risk (e.g., parts of Middle Asia), PP fiber improves ductility and reduces brittle failure.

Sustainable Infrastructure: PP fibers can even be combined with self-healing agents like superabsorbent polymers to enable autonomous crack repair in mortar and concrete over time.

Europe

In Europe, sustainability and durability are key drivers. The adoption of PP fiber for mortar is rising, especially in green building and infrastructure renovation markets. European standards (e.g., EN 14889) ensure fiber quality and performance, pushing manufacturers to deliver high-spec products. The trend toward lower-carbon construction also favors PP fiber, as it can reduce maintenance and improve service life.

USA

In the United States, PP fiber in mortar is gaining traction in industrial floors, bridges, and housing. According to industry data, PP fiber–reinforced sections in highway pavements have reduced lifecycle maintenance costs by up to 35%, due to lower cracking and no corrosion risk compared to steel reinforcement.

Moreover, compliance with ASTM C1116 and other synthetic fiber standards (Type III) ensures consistent performance.

Brazil

Brazil's booming construction market — from residential to infrastructure — increasingly relies on fiber-reinforced mortars to manage shrinkage cracking in hot, humid climates. PP fiber helps with crack control while being cost-effective compared to steel reinforcements. Local producers and importers are expanding supply, and high‑performance fibers such as those from Celix are likely to be used more in commercial and civil projects.

Middle Asia

In Middle Asia (Central Asian republics, parts of the Caucasus), the demand for durable and resilient construction materials is on the rise. Harsh climates, temperature extremes, and increasing seismic risk make PP fiber–reinforced mortar very attractive. In these regions, PP fiber is particularly valued for improving ductility, reducing microcracking, and enabling robust mortar performance in both new-build and renovation works.

To select the best PP fiber for mortar, here are actionable steps:

Define Your Application: Are you making a decorative plaster, structural shotcrete, or industrial floor overlay? Different uses need different fiber types (length, shape, dosage).

Match Specifications: Review technical data sheets from manufacturers like Celix. Ensure fiber length, tensile strength, and melting point meet your performance needs.

Trial Mix: Always run a pilot mix with and without PP fiber. Observe workability, slump, finishability, and crack behavior during curing.

Consider Local Standards: For example, in Europe check EN standards; in the USA check ASTM; in other regions, consult local construction codes.

Calculate Cost‑Benefit: While PP fiber adds upfront cost, it often reduces long-term maintenance. In many U.S. and Brazilian infrastructure projects, reduced repair cycles offset the cost.

Supplier Reliability: Use trusted brands like Celix that provide consistent quality, technical support, and datasheets.

Conclusion

Choosing the right PP fiber for mortar is not a one-size-fits-all decision. Technical specifications like fiber length, tensile strength, and thermal behavior matter. The fiber's role in applications — whether anti-crack plasters, shotcrete, or flooring — must align with project goals. Meanwhile, regional market trends in Europe, USA, Brazil, and Middle Asia highlight growing demand for high-performance, durable, and sustainable fiber-reinforced mortars.

For construction teams and material specifiers, partnering with reliable fiber brands like Celix ensures high-quality PP fiber tailored to your needs. By carefully matching fiber properties, dosage, and performance requirements, you can maximize the benefits of pp fiber for mortar—achieving crack control, durability, and long-term value.

References:

Research on Anti‑Cracking Performance of Polypropylene Fiber Reinforced Cement Mortar

Effect of polypropylene fibre on cementitious mortar early shrinkage cracking

Contact Us

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.