Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

Ever faced cracked mortars or inconsistent tile adhesives? Celix's premium HEMC (Methyl Hydroxyethyl Cellulose) solves these common construction headaches with unmatched performance.

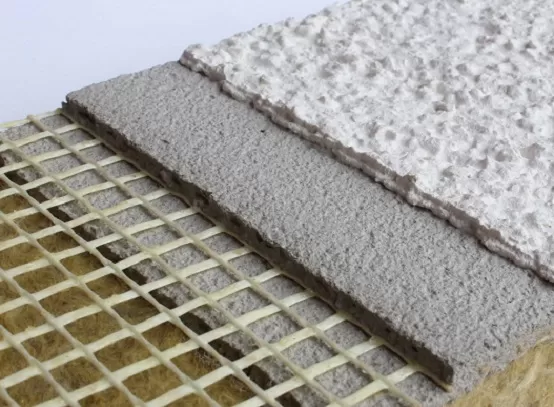

HEMC/MHEC enhances construction materials by improving water retention, workability, and adhesion. Celix's specialized formula ensures superior performance in mortars, tile adhesives, and gypsum-based products while reducing cracking and shrinkage.

Let's examine why top contractors worldwide trust Celix HEMC to deliver flawless results across critical applications.

Are drying cracks ruining your mortar applications? Celix HEMC keeps materials workable longer while preventing premature water loss.

HEMC acts as a multifunctional additive in dry mix mortars by retaining water for proper cement hydration, improving adhesion, and enhancing sag resistance. This results in stronger bonds and crack-free surfaces.

| Property | HEMC Contribution | Practical Impact |

| Water Retention | Forms protective colloid layer | Prevents rapid drying → Fewer cracks |

| Workability | Lubricates particles | Easier application → Labor savings |

| Open Time | Slows water evaporation | More adjustment time → Less waste |

| Adhesion | Increases cohesive strength | Better bond to substrates |

Technical Tip: For exterior applications, combine Celix HEMC with our VAE redispersible powder for exceptional weather resistance.

Frustrated with tiles slipping or weak bonds? Discover how Celix HEMC creates reliable, high-performance adhesives.

HEMC optimizes tile adhesives by providing excellent slip resistance, adjustability, and water retention. Celix's specialized grades ensure consistent quality across varying climate conditions.

1. Sagging Problems

Without HEMC: Heavy tiles slide downward

With Celix HEMC: Thixotropic properties prevent sag (tested to EN 12004 standards)

2. Climate Sensitivity

Conventional adhesives fail in humid conditions

Celix HEMC maintains performance from -20°C to 80°C

3. Short Working Time

Standard products set too quickly

Celix formulation allows 30+ minutes of adjustment

Product Selection Guide:

| Application | Recommended HEMC Grade | Key Feature |

| Ceramic Tiles | MHEC 75000S | Balanced slip resistance |

| Large Format Tiles | MHEC 100000 | High shear strength |

| Wet Areas | MHEC 15000SF | Fast water resistance development |

Facing pressure to go green without sacrificing performance? Celix HEMC delivers eco-friendly advantages that matter.

As a plant-derived additive, HEMC reduces VOC emissions and enables low-carbon construction materials. Celix's sustainable production process further minimizes environmental impact.

Environmental Benefits:

Renewable Origin: Derived from FSC-certified cellulose

Biodegradable: Breaks down naturally without microplastic pollution

Energy Efficient: Reduces need for curing protection → Lower jobsite energy use

Certifications Supporting Sustainability: ✔ LEED v4.1 compatible ✔ BREEAM recognized ✔ GreenGuard Gold eligible

Global Impact Example: A German prefab housing manufacturer achieved 35% lower embodied carbon by reformulating their systems with Celix HEMC, replacing petrochemical additives.

Future Outlook: With increasing regulations on construction emissions (like EU's EPBD), HEMC's role in sustainable building solutions will expand significantly.

Celix HEMC/MHEC delivers superior performance in construction materials through enhanced water retention, workability, and sustainability—helping builders achieve flawless results efficiently.

Contact Us

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.