Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

In Brazil's fast-evolving construction sector, the demand for high-performance tile adhesives has risen sharply. With large urban development projects and rising renovation activity in both residential and commercial markets, Brazilian manufacturers and applicators are looking for additives that improve consistency, workability, and long-term durability. Modified HEMC for tile adhesive has emerged as a key ingredient in modern formulations, delivering significant performance benefits over traditional additives. Premium cellulose ether products such as Celix Modified HEMC play a crucial role in meeting these industry needs.

Brazil is one of the world's leading markets for ceramic and porcelain tiles, driven by both aesthetic preferences and functional demands for durable surfaces. From São Paulo's commercial complexes to beachside residential developments in Rio de Janeiro, tiles are widely used due to their ease of maintenance and design versatility. According to local construction industry reports, tile installation remains a critical component of construction — not just for floors but also for walls, facades, and outdoor applications.

However, Brazil's varied climate — ranging from tropical humidity in the north to seasonal temperature swings in the south — presents challenges for tile adhesive performance. Adhesives must resist rapid water loss in hot, dry conditions and maintain adequate bond strength in areas of high humidity. This has accelerated adoption of advanced additive technologies such as Modified HEMC for tile adhesive, which enhance adhesive properties to meet those demands.

A defining feature of Brazil's construction environment is its climate. In many regions, particularly in the northeast and central parts of the country, high ambient temperatures and low relative humidity can accelerate moisture loss from fresh tile adhesive mortars. This rapid evaporation can lead to poor hydration of cementitious components, resulting in weaker bonds and higher risk of cracking or delamination.

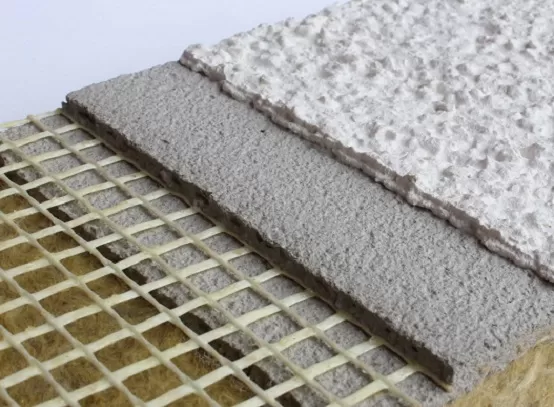

Modified HEMC (Hydroxyethyl Methyl Cellulose) acts as a water retention agent, absorbing and holding water within the adhesive mixture. This controlled water retention is fundamental because it ensures that the tile adhesive remains workable long enough for proper tile placement and that the cement fully hydrates to develop bond strength. The enhanced water retention capability directly improves adhesive reliability in Brazil's hot and dry conditions, reducing early moisture loss and enhancing curing consistency.

In addition to moisture control, Modified HEMC improves workability and rheology of tile adhesives. It increases viscosity in a manner that enhances spreadability while reducing the risk of sagging or slumping — particularly important for vertical tile applications on walls or facades. This makes adhesive application easier and more uniform, which is critical when dealing with large-format tiles or textured surfaces commonly used in Brazilian construction.

Brazilian construction professionals prioritize tile adhesives that deliver several key performance characteristics: strong bond strength, controlled open time, resistance to sagging, and adaptability to climate variations. In hot regions, open time — the period during which the adhesive remains tacky and workable — must be sufficient so that installers can position and adjust tiles without compromising performance. Modified HEMC increases open time, providing installers with flexibility and efficiency during application.

Brazil's building codes and standards increasingly emphasize quality and durability, incentivizing manufacturers to adopt advanced cellulose ether additives that improve overall tile adhesive performance. For example, premium adhesives designed for tropical environments often incorporate Modified HEMC to ensure that key performance targets — such as tensile adhesion strength and anti-slip performance — are met even under challenging conditions.

Moreover, Brazil's construction sector is highly competitive, with a growing emphasis on delivering high-quality finishes at lower life-cycle costs. Adhesives formulated with Modified HEMC not only meet performance requirements but also enhance installer satisfaction by reducing installation errors, minimizing tile movement, and supporting long-term durability.

Among Modified HEMC products on the market, Celix Modified HEMC for tile adhesive represents a reliable choice for Brazilian formulators and construction professionals. Celix's cellulose ether additives are developed with advanced surface treatment technology to ensure controlled hydration, consistent dispersion in dry-mix formulations, and enhanced stability under varying weather conditions.

Key benefits of Modified HEMC for tile adhesive include:

Superior Water Retention: Prevents rapid moisture loss in high temperatures, ensuring full cement hydration in adhesive systems.

Improved Workability: Enhances the smoothness and spreadability of tile adhesive mortars, making them easier to apply and reducing labor time.

Extended Open Time: Provides longer adjustment windows, crucial for large-format tile installations and precision layouts under hot conditions.

Better Sag Resistance: Reduces tile slip during installation, particularly on vertical surfaces, ensuring consistent application quality.

Enhanced Adhesion Strength: Improves bonding capacity between tile and substrate, contributing to long-lasting installations.

With customizable viscosity grades and quality control measures, Celix Modified HEMC products help manufacturers tailor their formulations to meet Brazil's unique climatic challenges while satisfying both performance standards and installer expectations.

As Brazil's construction market continues to expand and innovate, the demand for high-quality tile adhesives that deliver consistent, durable performance will only grow. Modified HEMC for tile adhesive has proven to be a key contributor to achieving these performance goals in hot and varied Brazilian climates. By enhancing water retention, workability, open time, and adhesion strength, Modified HEMC elevates ordinary cement tile adhesives to meet modern construction demands.

For Brazilian manufacturers and construction professionals seeking performance gains and formulation reliability, Celix Modified HEMC offers a robust additive solution that aligns with market expectations and ensures strong performance across diverse applications.

References:

Brazil Ceramic Tiles Market Size & Outlook, 2024-2030

Tile Adhesive Market Growth in Brazil

Contact Us

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.