Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

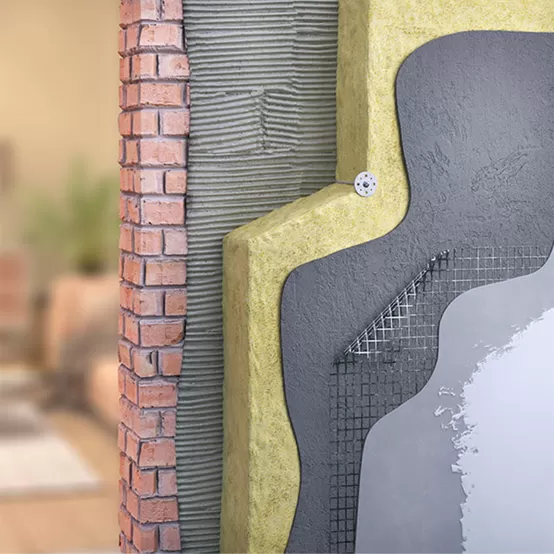

SHP, or silicone hydrophobic powder, is a powder that repels water. Making surfaces water-resistant while preserving vapor permeability is the fundamental purpose of silicone hydrophobic powder. As a result, waterproof building materials frequently incorporate it. Silicone hydrophobic powder can be used in EIFS, paint and coating, and render and plaster.

Model No.: SHP-1010

Type: Water Repellent Agent

Appearance: White Powder Substance

HS Code: 3824409000

Water Repellency

Creates a protective barrier that repels water from the material surface.

Improved Durability

Minimizes moisture damage and enhances the long-term strength of products.

Long-Lasting Appearance

Preserves a clean look by reducing staining and surface discoloration.

High Compatibility

It can be used in combination with adjuvants such as HPMC, RDP, Defoamer, and Starch Ether.

| Product Model | SHP - 1010 |

| Appearance | White free - flowing powder |

| Bulk Density | 250-400 g/L |

| Moisture Content | ≤3% |

| Fineness | 98% pass through 200 mesh |

| pH Value | 10 - 12 |

| Recommended Dosage | 0.15 - 0.35% |

Silicone Hydrophobic Powder (SHP) forms a robust water-repellent barrier on surfaces, effectively shielding them from water-induced damage and degradation. It further mitigates common construction issues, including efflorescence formation, mold proliferation, and freeze-thaw cycle-related deterioration. By reducing the water absorption rate of mortar, SHP prevents the occurrence of cracks and enhances the overall structural stability of the material.

EIFS are susceptible to moisture damage, and the addition of SHP addresses this by protecting the insulation and preventing issues like rot. SHP confers hydrophobic properties, particularly to the base and finish coats of the system. It also prevents waterborne stains, discolorations, and surface efflorescence, ensuring the finish remains visually appealing over time.

SHP reduces cracking risks caused by moisture absorption and freeze-thaw cycles. It functions by repelling liquid water to prevent material penetration, yet permits vapor escape—this helps cut down on internal condensation and dampness. Even in wet or humid settings, SHP also keeps the surface clean and fresh.

SHP improves coatings' UV resistance, maintaining their color and structural integrity. It also preserves surface appearance, ensuring long-lasting aesthetics. By preventing moisture buildup beneath the coating, SHP further reduces the risk of blistering or adhesion failure.

Contact Us

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

Quick Links

+8618330106777

+8618330106777

info@celixcellulose.com

info@celixcellulose.com

EN

EN

jp

jp  ko

ko  es

es  ru

ru  pt

pt  th

th  ar

ar  vi

vi  id

id  kk

kk