Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

| Model | RDP328 | RDP5030 | RDP7030 | RDP7040 | RDP7045 |

| Exterior | White free flowing powder | ||||

| Protective colloid | PVA | PVA | PVA | PVA | PVA |

| Solid content, % | 97-99 | 97-99 | 97-99 | 97-99 | 97-99 |

| Ash content, % | 17+-2 | 15+-2 | 13+-2 | 13+-2 | 13+-2 |

| Bulk density, g/| | 300-500 | 300-500 | 300-500 | 300-500 | 300-500 |

| Particle size, µm | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 |

| Minimum film forming temperature, ℃ | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 |

Excellent cohesion very good adhesion to critical substrates such as wood

Flexibility can be engineered without the need to add plasticizers

Good low-temperature film forming without additional coalescing agents

Glass transition temperatures (Tg) from high to low are possible

All modern polymer powders are produced without added APEOs

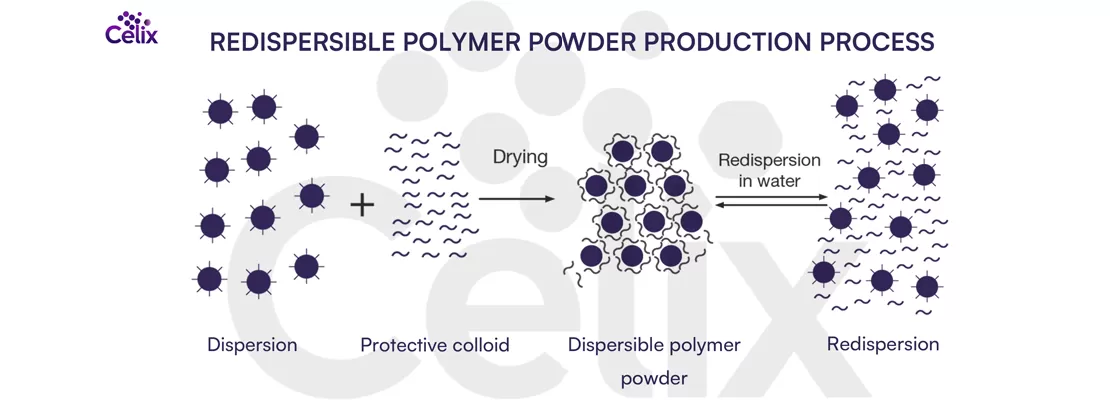

The manufacturing of Vinyl Acetate-Ethylene Copolymer Redispersible Polymer Powder (VAE RDP) starts with preparing VAE emulsion via emulsion polymerization, using vinyl acetate (VAc) and ethylene (E) as monomers. Key parameters like polymerization temperature, initiator dosage, and monomer ratio are precisely controlled to ensure uniform emulsion particle size distribution and qualified solid content. Next, the VAE emulsion is mixed with a protective colloid (e.g., polyvinyl alcohol) and a defoamer in fixed amounts, then thoroughly blended under constant-temperature stirring to form a stable slurry for drying, which prevents foam formation and particle agglomeration in subsequent steps.

The slurry is then fed into a spray dryer, atomized into tiny droplets by a high-pressure atomizer, and brought into countercurrent contact with hot air (inlet temp: 180-220℃, outlet temp: 80-100℃) for rapid moisture evaporation, forming a gas-solid mixture. Finally, the mixture is separated by a cyclone separator to collect dry solid particles, which are further sieved to remove impurities, resulting in fine, free-flowing VAE RDP finished products.

It's Redispersible Polymer Powder, usually a VAE polymer made into free-flowing powder via spray drying, redispersible in water.

Some Manufacturers include Celanese, Wacker, BASF, and Chinese firms like Sinopec, Celix specialized in polymer or construction chemical production.

It is widely used in dry-mix mortars (tile adhesive, skim coat), wall putty, and construction materials to boost adhesion, flexibility.

There isn't a fixed formula. However, the formula is the mainly polymer (e.g., VAE), protective colloid (PVA), defoamer, with a ratio adjusted by the performance needs.

Most non-hazardous, but may cause mild irritation if inhaled/contacted; follow storage/use guidelines (avoid dust inhalation).

RECOMMENDED PRODUCTS

Contact Us

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.