Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

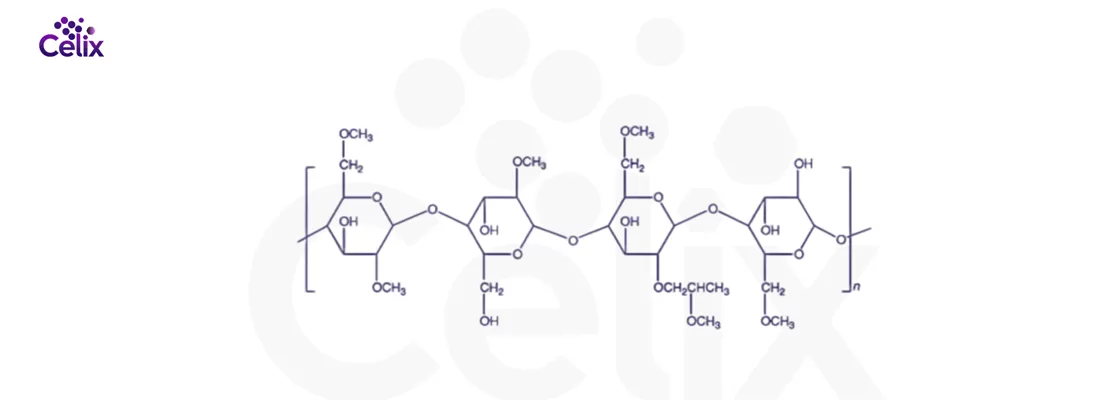

Hydroxyethyl Methyl Cellulose (HEMC/MHEC) is a nonionic natural polymer derived from the refine cotton linter. Like other methyl cellulose derivatives, methyl hydroxyethyl cellulose has many of the same advantages, including effective thickening and water retention.

Hydroxyethyl Methyl Cellulose (HEMC/MHEC) is a nonionic natural polymer derived from the refine cotton linter. Like other methyl cellulose derivatives, methyl hydroxyethyl cellulose has many of the same advantages, including effective thickening and water retention.

| Specification | EM-30U | EM-55U | EM-65U | EM-75U |

| Exterior | White or light yellow powder | |||

| Methoxyl, % | 18.0 - 24.0 | |||

| Hydroxyethyl, % | 8.0 - 16.0 | |||

| pH value | 5.0 - 8.5 | |||

| Moisture, % | ≤6 | |||

| Ash, % | ≤3 | |||

| Graininess | 100 mesh 98.5% pass, 80 mesh 100% pass | |||

| Viscosity(2%, 20℃, Mpa.s) | 24,000-45,000 | 45,000-60,000 | 55,000-65,000 | 65,000-75,000 |

| Gel temperature,℃ | 70-90 | |||

Adhesion Enhancement

Weather Resistance

Sustainability

Water Retention

Compatibility & Synergy

The production of hydroxyethyl methyl cellulose (HEMC) follows a similar process to HPMC, beginning with the alkali treatment of refined cotton. Ethylene oxide and chloromethane act as etherifying agents, introducing hydroxyethyl and methyl groups into the cellulose backbone under controlled temperature and pressure. After etherification, the product undergoes neutralization, washing, drying, and milling to yield the finished HEMC with the desired substitution degree.

At Celix, HEMC quality begins with carefully selected raw materials and continues through every step of production. Automated DCS systems ensure stable reaction conditions, while real-time monitoring safeguards viscosity, substitution, and consistency. Advanced testing methods like IR and GPC guarantee reliable performance and product uniformity, delivering confidence in every batch.

Hydroxyethyl methyl cellulose (HEMC) is widely used in construction materials like tile adhesives, wall putty, gypsum, and coatings to improve workability and water retention. It is also applied in personal care and detergent formulations as a thickener, stabilizer, and film-forming agent for consistent product performance.

Both HPMC and HEMC are cellulose ethers used for thickening, water retention, and stability. The key difference lies in substitution: HEMC introduces hydroxyethyl groups, enhancing salt and temperature resistance, while HPMC introduces hydroxypropyl groups, offering broader solubility. Choice depends on application demands in construction, detergents, or pharmaceuticals.

Celix guarantees HEMC quality through strict raw material selection, advanced DCS-controlled manufacturing, and real-time monitoring of viscosity and substitution. Every batch undergoes testing with infrared spectroscopy (IR) and gel permeation chromatography (GPC). These controls ensure consistent performance, reliability, and compliance with international standards for construction and industrial applications.

RECOMMENDED PRODUCTS

Contact Us

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.