Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

Research Development Details

The Celix's Owned Laboratory

Experimental Research Year

Contact Person

Self-leveling is a very advanced construction technology. Self-leveling mortar is a floor-leveling material. It's formed by mixing it with water to form a fluid liquid that flows and solidifies under gravity to form a smooth surface. Types include cement-based, epoxy-based, and gypsum-based self-leveling mortars.

The Self-leveling mortars are often used to replace traditional cement mortars, offering improved smoothness and gloss, making them suitable for high-end venues like exhibition halls and shops.

Perfect Leveling

It can correct the uneven substrates quickly and effectively.

Time Efficiency

It is allowing faster application and shorter project timelines.

Strong Foundation

It’s providing stability for subsequent floor coverings.

Durability

It's resisting cracks, shrinkage, and long-term wear.

The self-leveling mortar consist of cement, sand, and fillers modified by a range of additives such as HPMC, HEMC, HPS, PP fibers and VAD RDP powders.

Enhanced Flow and Consistency

Excellent Water Retention

Improved Workability

Crack & Shrinkage Resistance

Reliable Surface Quality

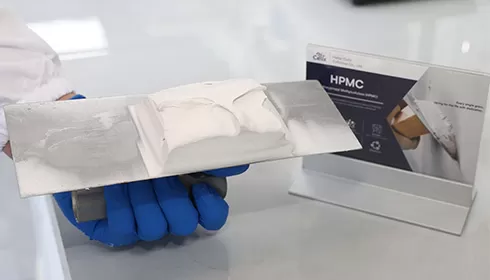

HPMC keeps water from evaporating too quickly and makes sure the cement is hydrated for strength. In order to guarantee a smooth surface, it also manages flow rate, viscosity, and stratification, or the separation of materials.

RDP polymer increases mortar's flexibility and resistance to deformation, lessens shrinkage cracking, and increases its resilience to impact and wear.When combined with cellulose ether, hydroxypropyl starch ether greatly improves the mortar's thixotropy and anti-settling qualities.

PP fiber can inhibit the microcracks caused by water loss and shrinkage during the plastic stage and initial hardening process of the mortar, thereby enhancing the integrity of the material.

Flexural and Compressive Strength Test

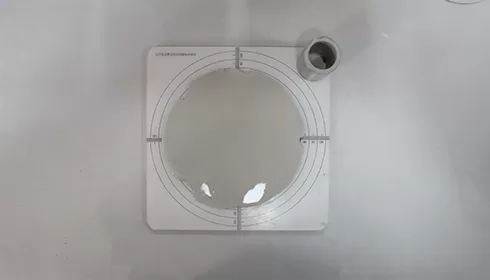

Flowability Test

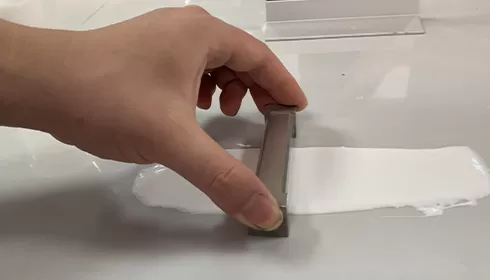

RDP Flexibility Test

By improving water retention, HPMC PM-4H ensures that the mixture maintains an ideal consistency, allowing it to spread smoothly and evenly across surfaces. This ensures better leveling performance, making it easier to achieve a flat, uniform finish. Additionally, this model extends the working time, providing ample time for adjustments before setting begins. Its unique properties help prevent premature drying and cracking, enhancing the overall quality and durability of the self-leveling compound. This makes HPMC a key component for achieving professional results in floor applications.

Contact Us

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.