Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

Research Development Details

The Celix's Owned Laboratory

Experimental Research Year

Contact Person

Gypsum mortar is a building material made primarily from gypsum, used for coating walls, ceilings, and partitions.

It is valued for its quick setting, smooth finish, and natural fire resistance, making it a preferred choice for modern interior construction.

Solve the Common Quality Problems

Gypsum mortar can effectively avoid quality problems such as "hollowing", "cracking" and "falling off" that are prone to occur in cement mortar, thereby improving the overall quality and durability of wall plastering.

Improved the Construction Efficiency:

Gypsum mortar offers excellent workability, significantly shortening construction cycles and increasing construction efficiency by 1.5 to 2 times compared to cement mortar. Its lightweight nature also reduces building loads and minimizes material waste during construction.

Elevated the Building Safety:

Gypsum mortar has excellent flame retardancy. In the event of a fire, Gypsum releases crystallized water, absorbing significant heat and slowing the spread of fire, providing time for escape.

Sustainability

The energy consumption and waste gas emissions of gypsum mortar production are much lower than those of cement production.

Economic Benefits:

Using gypsum mortar can shorten construction time, reduce rework, and improve labor productivity, resulting in better long-term economic benefits.

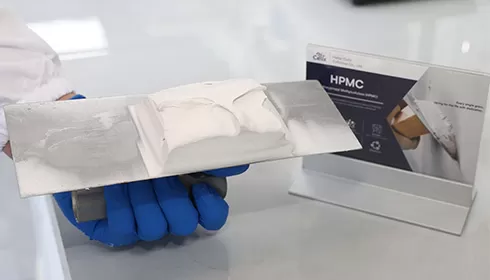

Generally, the customer will pick HPMC and Gypsum Retarder for the Gypsum Mortar to improve the workability, water retention and long open time.

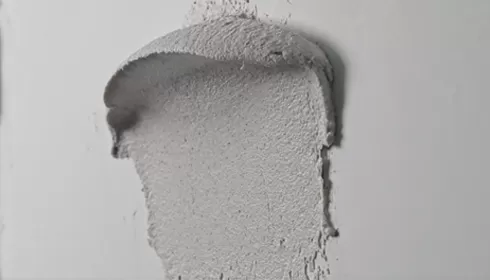

Optimized Workability

Excellent Water Retention

Sag Resistance

Extended Open Time

Durable Smooth Finish

With Celix cellulose ethers, gypsum mortar achieves a superior performance, flawless finish, and reliable durability so that it perfectly satisfies both builders and end-users. Especially in the Middle Asia market, HPMC could efficiently improves the gypsum based mortar consistancy and water retention, in order to satisfy the large water demand of gypsum based mortar.

| Grade | Model | Viscosity(mPa·s, 2% solution) | Application | Properties |

| Modified Grade | PM-Pro-G1 | 35,000 -43,000 | Hand | High thickening efficiency & Good sag resistance |

| Modified Grade | PM-Pro-G2 | 25,000-5,0000 | Machine | Easy workability & excellent sag resistance |

| Modified Grade | PM-Pro-G3 | 27,000-37,000 | Finishing | High water retention & Good workability |

| Modified Grade | PM-Pro-G4 | 25,000-35,000 | Joint Filler / Finishing | Fast dispersing effect & no lump & Easy workability |

| Pure Grade | PM-30U | 24,000-45,000 | Hand | High thickening efficiency & Good sag resistance |

Workability

Anti-Sagging

Consistency

Whether you're looking for lightweight density, excellent crack resistance, or extended workability with good fire resistance, Celix's Pure grade Cellulose Ethers and Modified grade 'Celix Pro' product range impart properties in modern gypsum mortar formulations that help meet demanding construction standards.

Contact Us

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.