Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

Research Development Details

The Celix's Owned Laboratory

Experimental Research Year

Contact Person

ETICS/EIFS (External Thermal Insulation Composite System/Exterior Insulation Finish System) is a type of thermal insulation board system.The system consists of multiple integrated composite layers, including insulation board, basecoat, reinforcement mesh and topcoat, ensuring functional integrity and durability.

EIFS/ETICS insulation systems provide a continuous thermal insulation layer for building facades by integrating waterproofing, thermal insulation and decorative coatings on the building's exterior surface.Its main function:

Thermal Insulation

This system forms a continuous insulating layer on the building's exterior, effectively preventing heat from escaping or entering the interior, thereby reducing the building's heating and cooling needs.

Energy Savings and Cost Reduction

By reducing reliance on heating and air conditioning systems, EIFS/ETICS systems can significantly reduce energy consumption, thereby saving energy costs.

Waterproofing

The system incorporates a waterproof layer to protect the building's exterior from rain and other moisture.

Improved Indoor Environment

A continuous insulation layer helps maintain a stable indoor temperature, improving indoor climate control and increasing occupant comfort.

Decoration and Protection

The system is ultimately covered with a durable decorative coating that not only enhances the building's appearance but also provides a protective layer against environmental elements.

Flexibility and Adaptability

EIFS/ETICS are suitable for a wide range of building types, offering architects a high degree of creative freedom and aesthetic choice.

EIFS & ETICS system demands the reliable adhesion, flexibility, and weather resistance,which is provided exactly by Celix pure grade cellulose ethers.

Enhance Adhesion

Improve Flexibility

Excellent Water Retention

Boost Workability

Ensure Weather Resistance

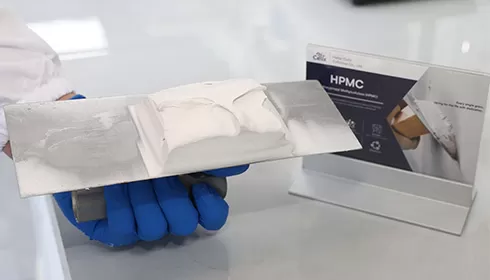

The HPMC and HEMC gives the cement enough time to hydrate and reach its ultimate strength by preventing the insulating board from absorbing the water in the mortar too rapidly.

By strengthening the binding between mortar and insulation boards and increasing the flexibility of the hardened mortar, the VAE RDP improves impact resistance and prevents cracking in the insulation system by allowing it to bear thermal stress brought on by temperature changes.

| Grade | Model | Viscosity(mPa·s, 2% solution) | Application | Properties |

| Pure Grade | PM-55U | 45000-60000 | EIFS/ETICS | Excellent slip resistance & Good open time |

| Pure Grade | PM-65U | 55000-65000 | EIFS/ETICS | Excellent workability & Good adhesion strength |

| Pure Grade | PM-75U | 65000-75000 | EIFS/ETICS | Excellent adhesion strength & Good open time |

| Modified Grade | PM-Pro-E20U | 14,000-22,000 | EIFS/ETICS | Excellent workability & Good sag resistance |

| Modified Grade | PM-Pro-E30U | 25,000 -35,000 | EIFS/ETICS | Excellent slip resistance & Good open time |

| Modified Grade | PM-Pro-E45U | 40,000 - 50,000 | EIFS/ETICS | Excellent open time & Less stickiness |

| Modified Grade | EM-Pro-E40U | 35,000-45,000 | EIFS/ETICS | Good heat resistance, excellent workability |

| Modified Grade | EM-Pro-E55U | 45,000-60,000 | EIFS/ETICS | Excellent open time, long open time |

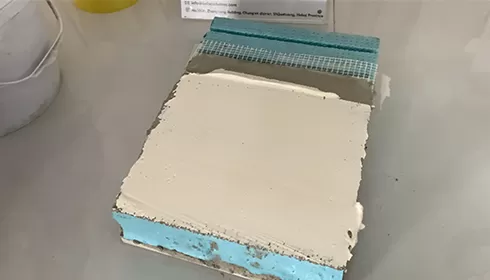

Crack Resistance After Dry

Mesh fiber embedment

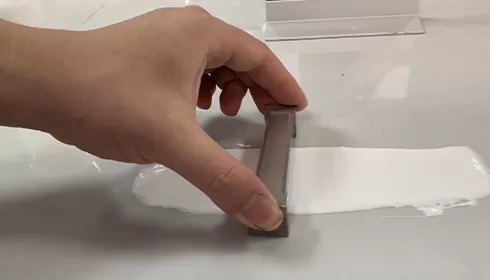

RDP Fliexibility Test

By enhancing water retention, Celix Pro Series HPMC ensures a smooth, consistent texture, making the mixture easier to apply and spread evenly over surfaces. It also increases the open time, allowing workers more flexibility and time to adjust the application. The addition of HPMC helps prevent early drying and cracking, contributing to a more durable and professional finish. This makes it essential for achieving high-quality, efficient results in external insulation applications.

Contact Us

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.