Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

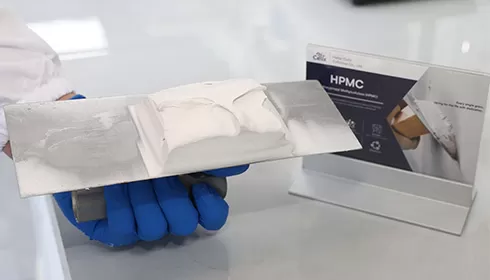

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

Research Development Details

The Celix's Owned Laboratory

Experimental Research Year

Contact Person

Dry-mix mortar is a premixed building material precisely measured and mixed in a factory. It consists primarily of dry, sieved aggregates (such as quartz sand), inorganic binders (such as cement), and various additives formulated in specific proportions.

The Dry mix mortar is delivered to the construction site in granular or powdered form, either in bags or in bulk. Before use, simply add water and mix according to regulations. It can be directly used in projects such as masonry, plastering, and floor construction. It offers advantages such as stable quality, convenient construction, and reduced waste and dust.

Stable Quality

Factory-produced, precise mix ratios, stable performance, and strength indicators surpass those of traditional on-site mixed mortar.

Easy Construction

It eliminates the tedious on-site measurement and mixing process; simply add water and use, improving construction efficiency.

Environmental Protection

It can reduces the on-site dust emissions and construction material waste.

Improved Workability

Increased Water Retention

Enhanced Durability

Consistent Performance

Enhanced Adhesion

elix HEMC and HPMC can increase the workability of dry mix mortar by lowering water demand, improving adhesion, and decreasing segregation.

Celix HEC can improve dry mix mortar's water retention, preventing cracking and promoting better curing.

By enhancing strength, decreasing shrinkage, and improving abrasion resistance, Celix RDP can prolong the life of dry mix mortar.

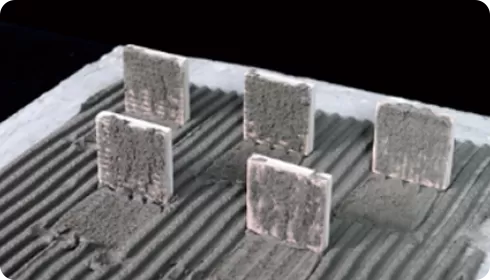

Open time test

Anti-slipping test

28 days coverage test

Whether you're looking for slip resistance, good adhesion to different substrates, or resistance to a wide range of climatic conditions, Celix's Pure grade Cellulose Ethers and Modified grade 'Celix Pro' product range impart properties in cement-based mortar formulations that help meet modern building industry standards.

Contact Us

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.