Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.

Research Development Details

The Celix's Owned Laboratory

Experimental Research Year

Contact Person

Cement plaster is an interior coating of sand, cement, and water applied in a thinner layer, creating a smooth, uniform surface for painting, wallpapering, or decorative finishes.

By using cement mixed mortar, the surface of the base becomes flat, smooth and clean. It’s good for laying the foundation for subsequent decoration such as tiling and painting, and at the same time enhancing the waterproof and crack resistance of the base.

Protective Effects

The plaster layer protects the building from the elements, such as wind, rain, snow, and sun, extending the life of the wall.Plastering effectively improves the building's ability to resist moisture and weathering.

Leveling and Smoothing

After a building structure is completed, plastering can create a smooth and even surface for walls and floors, creating a good base for subsequent decorative work.It can be used to fill gaps, cracks, and irregularities in a building's surface.The flat surface provides a stable foundation for subsequent decoration works such as painting and tiling.

Enhanced Adhesion and Structure

With layered plastering, the base layer ensures a good bond with the wall, ceiling, and floor, preventing separation between the plaster layer and the base. This tight bond between the plaster layer and the base enhances the integrity of the wall.

Improved Thermal Insulation

The plaster layer can improve the thermal performance of a building and provide a certain degree of thermal insulation.

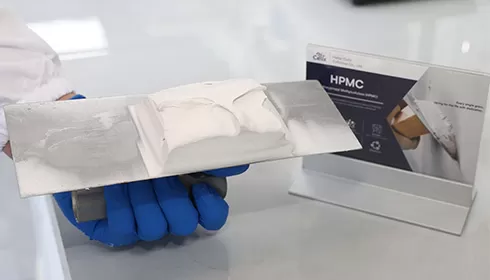

Cement render and plaster require both strength and smooth finish, and Celix pure grade cellulose ethers bring the perfect balance of performance and workability.

Enhance Water Retention

Improve Workability & Spreadability

Increase Adhesion

Reduce Shrinkage & Cracks

Deliver Consistent Results

The additives like HPMC, MHEC, and RDP improve workability and performance. HPMC primarily improves the water retention, workability, and workability of cement plaster mortar, reducing cracking caused by rapid water loss. The functions of HEMC similarly to HPMC, enhancing the water retention, consistency, and sag resistance of cement plaster mortar, while also improving the adhesion between the mortar and the substrate.

RDP significantly improves the bond strength, flexibility, and crack resistance of cement plaster mortar, enhancing the mortar's weather resistance and water resistance.

| Grade | Model | Viscosity(mPa·s, 2% solution) | Application | Properties |

| Pure Grade | PM-55U | 45000-60000 | Cement based Render | Excellent workability & Less retardation of cement hydration |

| Pure Grade | PM-65U | 55000-65000 | Cement based Render | Excellent workability & Good sag resistance |

| Pure Grade | PM-75U | 65000-75000 | Cement based Render | Excellent sagging resistance & Easy workability |

Cement consistency Test

Cement Plaster Performance Test

Water Retention Test

Whether you're looking for slip resistance, good adhesion to different substrates, or resistance to a wide range of climatic conditions, Celix's Pure grade Cellulose Ethers and Modified grade 'Celix Pro' product range impart properties in cement-based mortar formulations that help meet modern building industry standards.

Contact Us

Celix Cellulose Co., Ltd, is an integrated chemical cellulose manufacturer with in-house R&D, factories, and global sales sites.

Our products include HPMC, HEC, MHEC, VAE RDP, PCE, PVA, Defoamers, PP fibers, HPS, SHP and Gypsum Retarder.